Scientists have developed a novel approach that can help create safer and long-lasting lithium-ion batteries...

Scientists have developed a novel approach that can help create safer and long-lasting lithium-ion batteries. Combined with an automated reactor system, the mathematical x-framework allows unlimited customization of full concentration gradient (FCGs) with independent parameter control, leading to lithium-ion batteries (LIBs) with enhanced safety and stability.

“Unlike conventional methods, where adjusting one parameter affects the others, our approach allows independent and precise control over multiple descriptors, including average composition, slope, and curvature,” said Hyun Deog Yoo, Associate Professor from the Department of Chemistry and the Institute for Future Earth at Pusan National University, Korea.

Enhanced performance of lithium-ion batteries

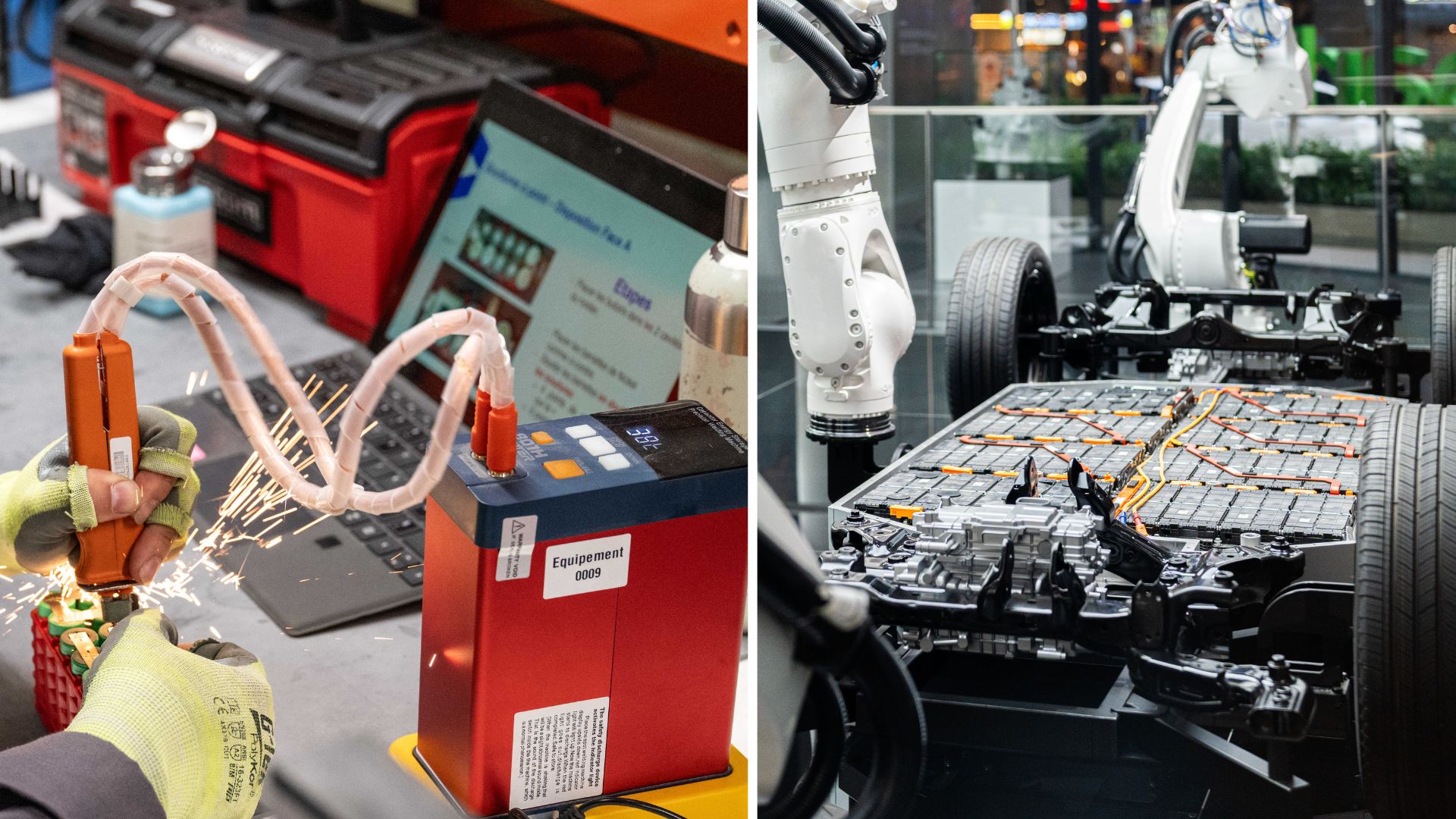

At a time when the demand for electric vehicles is on the rise, researchers are working to enhance the performance of lithium-ion batteries (LIBs).

The performance and stability of LIBs largely depend on the cathode material, which can account for nearly 40–45% of the total battery cost. Among cutting-edge technologies, high-nickel cathodes stand out for their high energy density and cost efficiency.

However, increasing the nickel content also intensifies side reactions, severely compromising interfacial robustness and mechanical integrity—factors that limit large-scale applications, according to researchers.

Promising solution

Scientists revealed that a promising solution is the use of full concentration gradient (FCG) or core–shell designs.

They pointed out that traditionally, FCG cathodes are synthesized via a coprecipitation method involving two tanks of metal precursor solutions.

The first tank, rich in nickel (Ni), feeds directly into the reactor.

The second tank, containing cobalt (Co) and manganese (Mn), is mixed into the first to reduce the Ni concentration over time. In conventional systems, the flow rate of this second tank is fixed, meaning only one specific gradient can be achieved for a given average composition, according to a press release.

In the study, researchers revealed that they overcame this limitation by expressing the flow rate of the second tank as a time-dependent mathematical function. This innovation allows independent tuning of the average composition, slope, and curvature—enabling the generation of a virtually unlimited range of concentration gradients using just two tanks.

Integrating approach with an automated reactor system

By integrating this approach with an automated reactor system, the team successfully synthesized five FCG Ni0.8Co0.1Mn0.1(OH)2 precursors with finely tuned gradients, verified through two- and three-dimensional elemental mapping, according to the experiment.

“For this purpose, we assembled an outstanding international research team, collaborating with laboratories at the University of Illinois Chicago, Argonne National Laboratory, and several institutes across Korea and the United States,” said Dr. Yoo.

“My lab focused on designing and synthesizing FCG cathodes, while most of the 2D and 3D imaging analyses were conducted by the groups of Prof. Jordi Cabana and Prof. Robert F. Klie. We feel truly privileged to have been part of such a remarkable collaboration.”